USAGE AND MAINTENANCE

In order to have a great working with NBEE 3D printer, it is important to maintain it correctly. In this chapter the most important maintenance tips are described. It is recommended to read them carefully in order to achieve the best results with your printer.

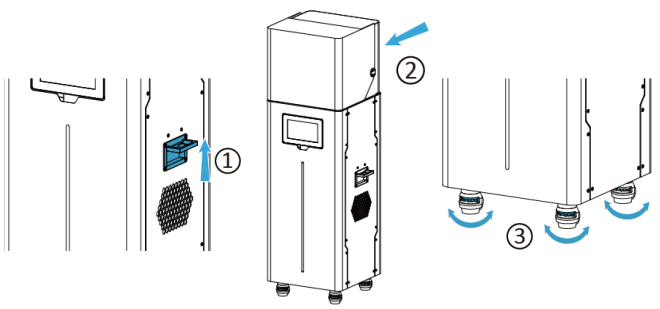

PRINTER PLACEMENT AND LEVELING

If you need to move the printer to a new location, pull out the handles on two sides. Pull the printer while holding the upper cover to prevent it from flipping down. Place the printer on a steady leveled floor.

To level the printer, turn the leveling screw on the four wheels to extend out the leveling foot until all four feet touch the floor and hold the printer steady.

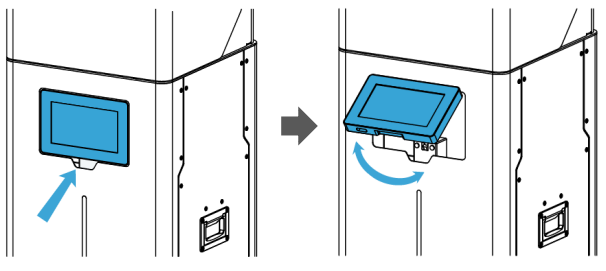

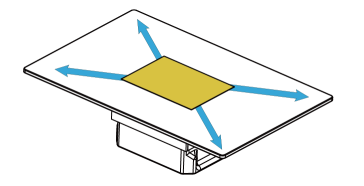

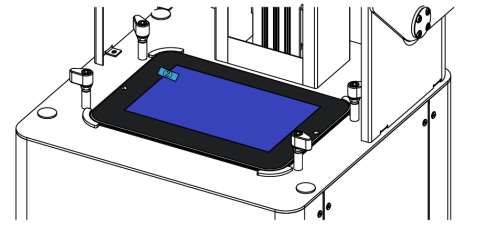

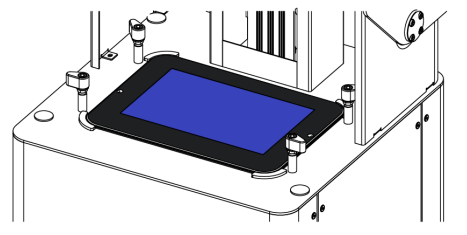

The touch screen of NBEE can be flipped up as shown in the following figure. It is recommended to return the screen to the upright position while moving the printer.

BUILD PLATFORM

The Build Platform is the platform where the first layer of the model burns in-to, its levelness and roughness are crucial to successful prints.

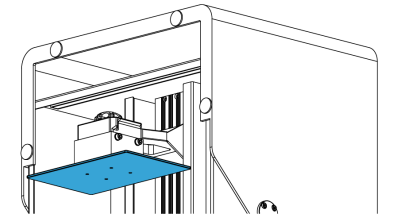

INSTALLATION AND REMOVAL OF BUILD PLATFORM

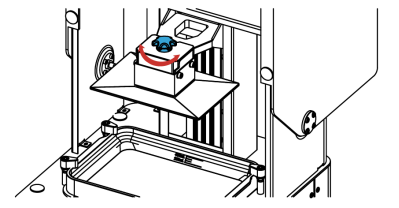

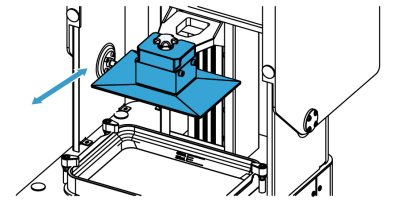

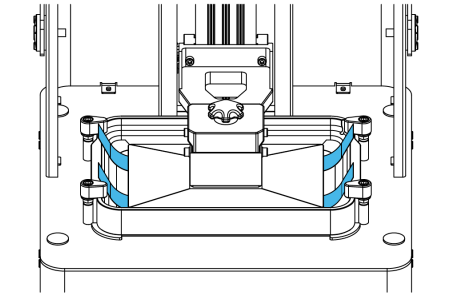

1. Turn the platform locking screw clockwise to lock (Turn the platform locking screw counterclockwise to unlock).

2. Install or remove the platform.

SANDING BUILD PLATFORM

After the platform has been used for a long time, its surface will become smooth which leads to poor model adhesion and increases the printing failure rate. To deal with this problem, users need to sand the platform.

1. Clean the platform surface with alcohol.

2. Grind the surface into a grid shape with the sandpaper delivered with the machine.

3. Clean the platform with alcohol and a soft cloth again to make sure there is no residue left.

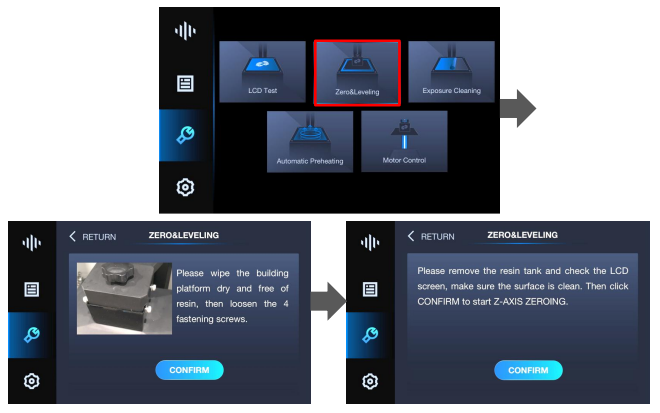

RESET Z-axis ZERO POSITION AND LEVELING BUILD PLATFORM

1. Prepare the four paper slips and the Hexagon Wrench in the accessory box sent with printer.

2. Make sure the bottom of Platform is clean and dry.

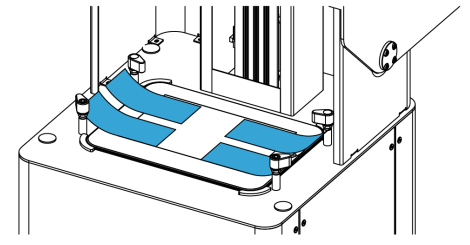

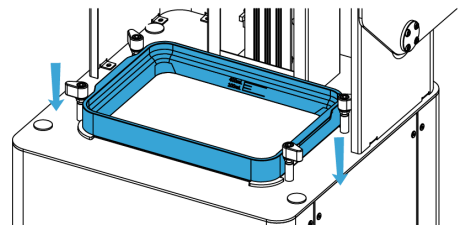

3. Turn the four lock blocks and take Resin Tank off and then put four pieces of paper slips at the four corners of LCD screen.

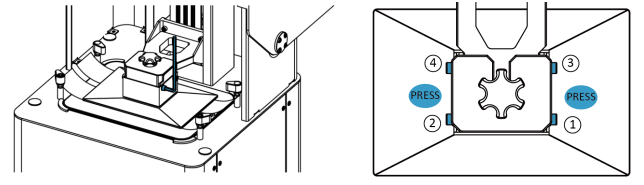

4. Loosen the four screws with Hexagon Wrench by turning counter-clockwise.

5. Click TOOLS/ZERO&LEVELING, then read the introduction and click CONFIRM twice to start.

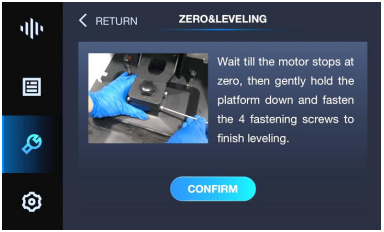

6. After Build Platform moves to the lowest position and stops, press the plate down and tighten the four screws with Hexagon Wrench by turning clockwise-as the picture shows.

7. Click CONFIRM to finish.

8. Then choose the 50mm option and click the arrow. Tightening the four M5 screws.

9. Install the Resin Tank and repeat step 5. Wait until the Platform stops, Try to pull out paper from any directions. If you can feel the frictional force between Platform and paper, that means it is zeroed and leveled successfully.

CLEAN BUILD PLATFORM

When printing fails, there may be residues on the platform which needs to be cleaned in time to avoid damage to the screen.

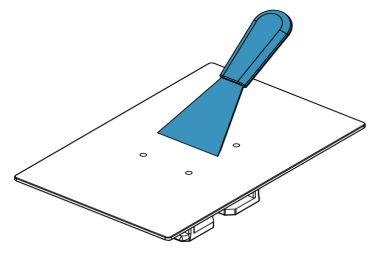

Please use the Shovel delivered with the printer to remove the residues (please dispose of solidified materials and waste resin properly).

Notes

1. After removal of model, please clean Build Platform thoroughly, any leftover bits may damage the Resin Tank or LCD.

2. Please be careful and do not hurt yourself.

RESIN TANK

The Resin Tank is a crucial part for a successful print job, and requires constant maintenance and regular replacement.

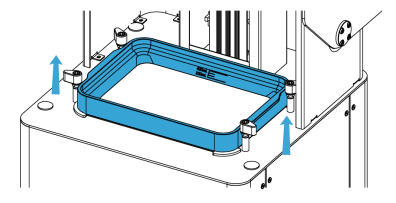

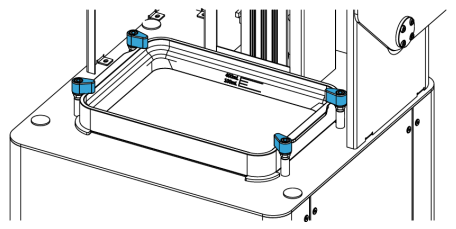

INSTALLATION

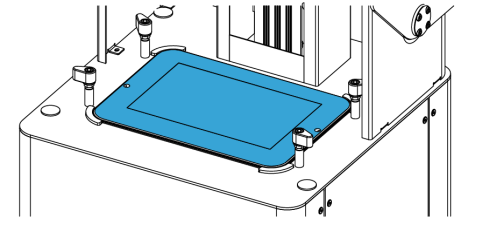

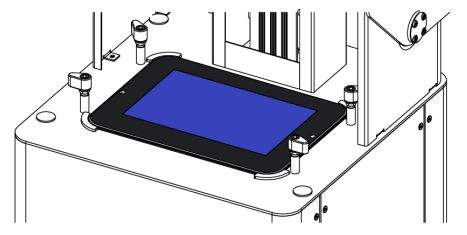

1. Make sure the LCD is clean and dry.

2. Put Resin Tank onto the LCD screen.

3. Turn the four lock blocks to lock the Resin Tank.

4. Make sure the Resin Tank is stably locked to get best performance.

CLEAN RESIN TANK

When printing fails, there may be residues in the Resin Tank which needs to be cleaned in time to avoid damage to the screen.

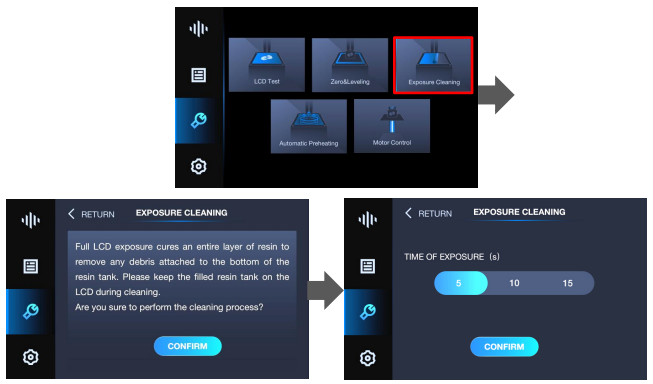

When residues are small in number and big in volume, use the cards delivered with the machine to clean; when residues are big in number and small in volume, it is recommended to use the Full Screen Clean function as following.

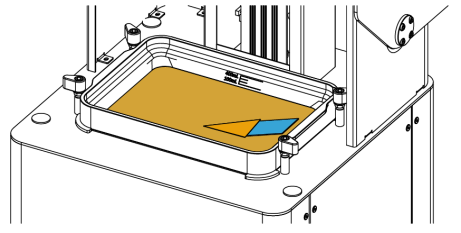

1. Click TOOLS/EXPOSURE CLEANING, choose the time and click CONFIRM to start exposure cleaning. Repeat if necessary.

2. After the exposure is done, gently scrape off the whole piece of cured resin from Tank with a paper card. DO NOT use the scrapper, since this may damage the film and cause a severe leak.

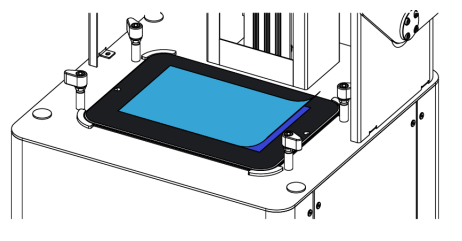

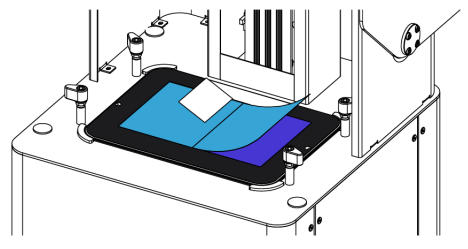

CHANGE LCD PROTECTIVE FILM

There is a protective film on the LCD. If the film is scratched or dirty with cured resin, you should change with a new protective film. Please keep one protective film on the LCD or the resin cured will left permanent damage to LCD.

1. Peel off the old film.

2. Clean the surface of LCD and make sure there is no dust and residue left.

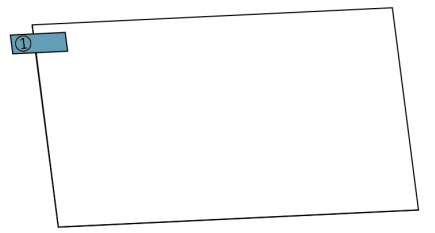

3. Take out a new film and peel off the cover film marked ‘①’.

4. Using a card and cloth to paste the film onto the surface of LCD.

5. Peel off the cover film marked ‘②’.

6. Any air bubbles between film and LCD will disappear automatically in a period of time.

SUGGESTION

1. After taking off resin tank, please place it on a clean table to avoid scratch.

2. When you slice a file by UNIZ Dental software, we recommend saving the sliced file to a solid state drive (SSD) for faster storage speed.

3. Please check whether there is dross left on Build Platform or at bottom of resin tank before each printing. If there is dross left on Build Platform, clean it with a scraper. If there is dross left in resin tank, you could use Exposure Cleaning function to cure and clean.

4. Please well mix the resin in resin tank by stirring with a hard cardboard like business card before each printing.

5. Please keep the printer stable to avoid disturbing while printing

6. Please keep the Cover in position while printing.

7. Please check and clean the Build Platform and Resin Tank after each print.

8. Please clean resin dropped incidentally on LCD screen, cover immediately.

9. Please drill a hole at the side of the bottom of a model if it is a closed hollowed model.

10. Please keep the printer and resin tank in a ventilated place, avoiding straight sunlight.

11. Use 80~200 mesh filter to filter the resin when put it back to bottle for storage.

12. Do Not let child close or operate the printer to avoid harm to child or damage to printer.

13. Please do NOT move printer when there is resin left in resin tank to avoid spilling.

14. Please do NOT gaze LCD screen when doing test print without Resin Tank and Build Platform.

15. Please do NOT leave resin in resin tank for more than 24 hours if not print.