After President Trump and the CDC advised all Americans wear a mask in public to prevent spreading the coronavirus, a lot of people experienced ear pain due to wearing a mask for an extended period of time. As a result, the 3D printing community came up with various solutions to relieve ear pains and provide comfort in wearing masks.

(Figure 1. mask extender designs. Source: thingiverse)

There are so many designs of mask extenders, but we found there are two main problems with current designs: Printing materials and slip.

Printing Materials Problem

Most mask extenders need to be printed with flexible materials like TPU, which is an uncommon material in all 3D printing materials. The most material used in the 3D printing market is “hard” material. Using materials with harder or rigid properties to print mask extenders would make the part easier to break.

(Figure 2. an example of flexible material. Photo by UNIZ)

There are millions of 3D printer users all over the world, but due to lack of flexible material, many of them cannot 3D print mask extenders.

Slip problem

The ideal wearing method of mask extender should be like this:

(Figure 3. ideal wearing method of mask extender. Illustration by GMBoy)

However, the extender can easily slip off due to smooth hair. Another way to use the extender is depicted in the next illustration below; however the elastic from the mask is still putting pressure on the top of the ear.

(Figure 4. elastic putting pressure on ears. Illustration by GMBoy)

In the next illustration, the extender is slipped to the back of the neck, but the mask would be pressed tight over the nose and cheek. Using the extender this way would relieve pressure on the ears but press into the skin of the nose and cheek.

(Figure 5. elastic putting pressure on nose and cheek. Illustration by GMBoy)

The UNIZ team designed a “Never Slip” mask extender to resolve all above problems.

(Figure 6. design of UNIZ mask extender. Model by YY Lee)

These extenders are to be connected by an elastic or cloth tie, whose length can be adjusted based on the individual’s head size.

(Figure 7. UNIZ mask extender. Photo by UNIZ)

When worn, put it on the head as illustrated in the photo below. The tie and mask will remain secure on the head while sparing the ears of pressure from the mask’s elastic ties.

(Figure 8. wear UNIZ "never slip" mask extender. Photo by UNIZ)

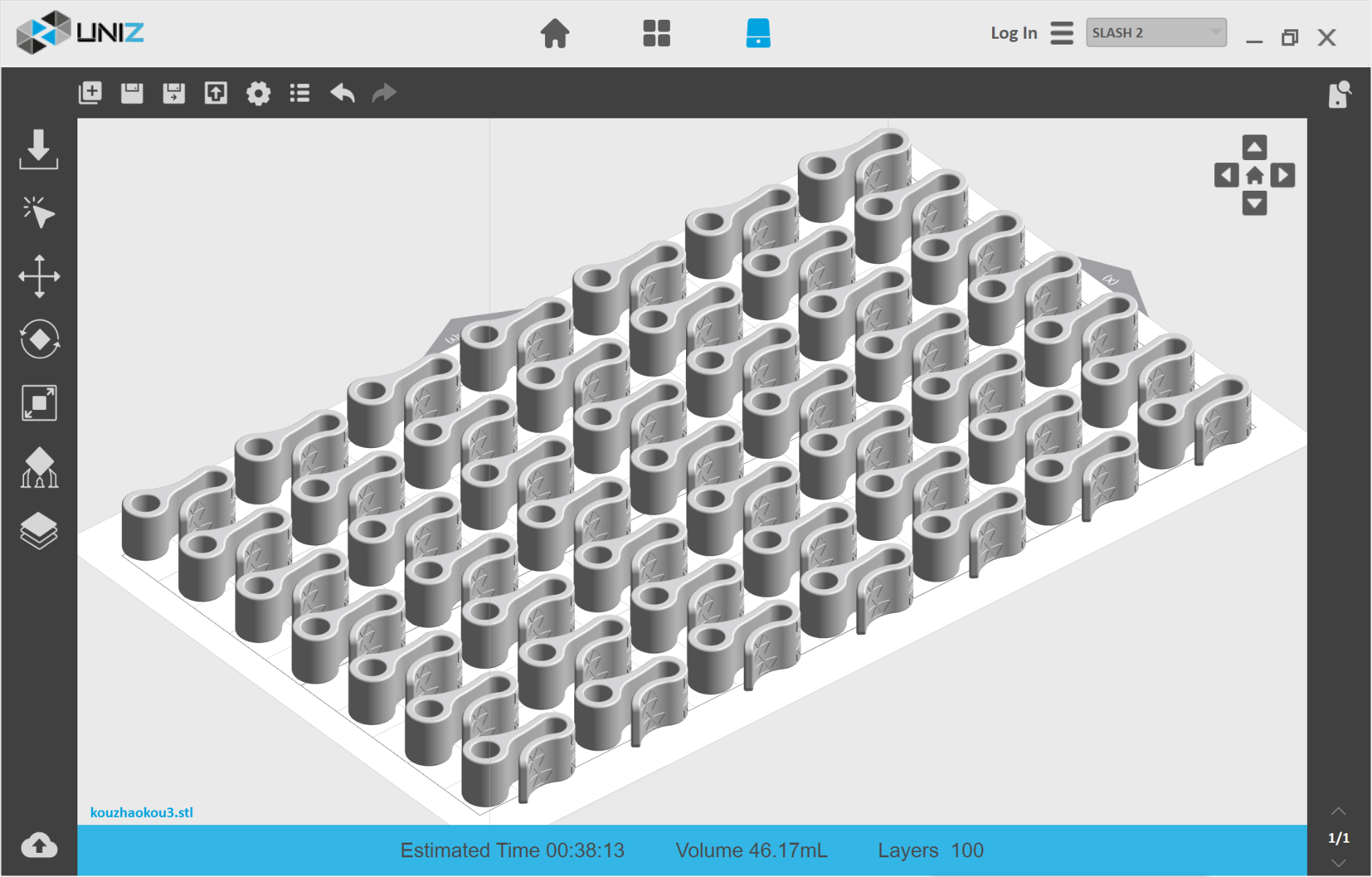

This extender can be 3D printed very easily without the need for additional supports. We used the SLASH 2 3D printer to 3D print 49 pieces of extender in one shot within about half an hour. If one SLASH 2 works for 8 hours daily, it can print more than 300 pairs of extenders. (click to learn more about SLASH 2: https://www.uniz.com/cn_zh/page/3d-printers-slash2/).

This mask extender can be printed with most material types, no matter flexible or “hard” it is.

(Figure 9. Full batch print in UNIZ software. Picture by UNIZ)

With an ergonomic design, the curve of this extender makes contact on the head more comfortable. Rounded corners could avoid hooking or scratching into the scalp. The outside of the hook part and the inner side are designed to prevent mask tie from slipping out. We also made a bigger hole for the tie to pass through. Even shoelaces can pass the hole; using thicker ties can reduce pressure on the head.

(Figure 10. Bigger hole for tie to pass through. Photo by UNIZ)

Now you can download this extender file from the Cloud model store in UNIZ software directly.

Beside Mask extender, UNIZ also developed a series of devices for prevention COVID-19 such as face shield, mask multiplier, goggles, hand-free door opener, etc. If you need any 3D printed products intended to prevent or treat COVID-19, please email covid-19@uniz.com

One More Thing…

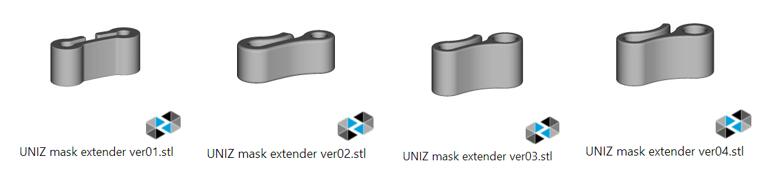

We have optimized the extender design four times.

In version 1, we used two hook designs, but found that the tie could easily slip off. In addition, the surface that would come in contact with the head is flat and not comfortable.

In version 2, we changed one hook to a hole for tie and added an ergonomic curve. However, the extender size was a little small. It was difficult to pick up by people who have larger hands.

In version 3, we increased extender size. But found the hook was too tight to hang the mask tie. The hole was too small for a thick tie as well.

In version 4, we enlarged hook gap and hole diameter. Designed to be comfortable and versatile, we finalized the model and published it on the UNIZ store.

(Figure 11. Four versions of mask extender design. Picture by UNIZ)

During the process, the designer 3D printed his design at once when he modified, and optimized his design based on the 3D printed result. The whole process was done within half a day. This speed present the advantage of 3D printing technology that cannot be reached by traditional module manufacture.