Dentistry

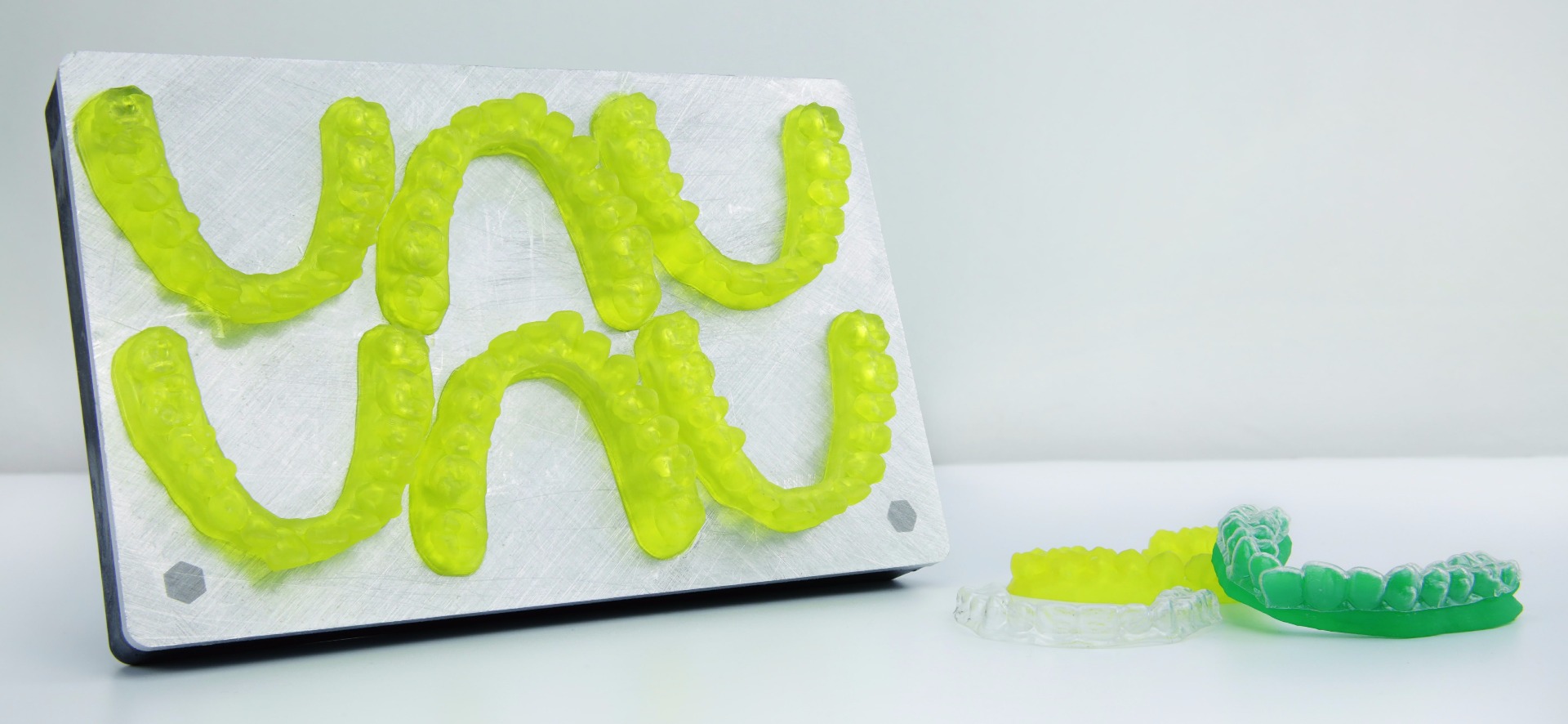

Modern dentistry heavily relies on the ability to produce small, complex components that fit perfectly inside the mouth. Every set of teeth is unique, meaning that every dental appliance has to be custom-made.

Traditional processes for fabricating dental parts rely heavily on the skill of a craftsman and mean that errors or variations are not uncommon while the multistage nature of investment casting means that small defects are often compounded. The need to insert the orthodontic components into a harsh environment that is not easily accessible while achieving a perfect fit means that highly complex, accurate geometries are needed.

SLASH 3D printing technology in dentistry have increased accuracy, eased delivery and decreased chair time, thus allowing dental teams to provide more effective treatment. In the SLA process, once the digital image is obtained, we utilize 3D modeling software to cut the final image into horizontal layers, and prints these in increments to create the final product while the layers are light cured, and the final step is to cure the entire model.